Hazard classification is a vital aspect of workplace safety that involves categorizing hazardous materials and substances based on their potential risks and characteristics. By accurately classifying hazards, employers can effectively communicate the associated risks to employees, take necessary precautions, and ensure compliance with regulatory standards. In this article, we will explore the concept of hazard classification, its importance, regulatory agencies and standards, the hazard communication (HazCom) process, labeling and safety data sheets, training requirements, the development of a hazard communication program, challenges faced, and GHS Hazard Sign .

Regulatory Agencies and Standards

Several regulatory agencies and standards provide guidelines and requirements for hazard classification. The Occupational Safety and Health Administration (OSHA) is a prominent regulatory agency in the United States that sets standards for workplace safety. OSHA’s Hazard Communication Standard (HCS) requires employers to classify and communicate hazards effectively.

Another important standard is the Globally Harmonized System (GHS), which is an internationally recognized framework for hazard communication. GHS provides a standardized approach to hazard classification, labeling, and safety data sheets across different countries, making it easier for companies to communicate hazards globally.

Additionally, the National Fire Protection Association (NFPA) developed the NFPA 704 standard, commonly known as the “fire diamond.” This standard provides a quick visual reference for identifying the health, flammability, and reactivity hazards of chemicals.

Understand Hazard Classification

Hazard classification is the systematic process of identifying and categorizing hazards based on their inherent properties and potential risks. It plays a crucial role in maintaining a safe working environment and protecting employees from harm. Through hazard classification, employers can identify and communicate the specific hazards associated with different substances, chemicals, and materials present in the workplace.

Hazard classification is a vital process in identifying and categorizing various hazards based on their characteristics and potential risks. This classification helps organizations and individuals better understand the nature of hazards and implement appropriate safety measures. Hazard classes and their applicable categories provide a standardized framework for classifying hazards. Let’s take a closer look at the hazard classes and their associated categories.

Physical Hazards

Physical hazards are hazards that can cause physical harm or damage to property. They encompass a wide range of hazards, including explosives, flammable materials, corrosives, and reactive substances. Here are some examples of hazard classes and their associated categories:

| Hazard Class | Associated Hazard Category |

|---|---|

| Explosives | Divisions 1.1-1.6 (1.1 being the most hazardous, 1.6 the least) |

| Flammable gases | Categories 1 and 2 |

| Flammable aerosols | Categories 1 and 2 |

| Oxidizing gases | Category 1 |

| Gases under pressure | Compressed gas, Liquefied gas, Dissolved gas, Refrigerated liquefied gas |

| Flammable liquids | Categories 1 – 4 |

| Flammable solids | Categories 1 and 2 |

| Self-reactive substances | Types A-G |

| Pyrophoric solids | Category 1 |

| Pyrophoric liquids | Category 1 |

| Self-heating substances | Categories 1 and 2 |

| Substances which in contact with water emit flammable gases | Categories 1 – 3 |

| Oxidizing liquids | Categories 1 – 3 |

| Oxidizing solids | Categories 1 – 3 |

| Organic peroxides | Types A-G |

| Substances corrosive to metal | Category 1 |

Health Hazards

Health hazards refer to substances or conditions that can pose risks to human health. These hazards include toxic materials, irritants, sensitizers, and substances that can cause acute or chronic effects. Here are some examples of hazard classes and their associated categories for health hazards:

| Hazard Class | Associated Hazard Category |

|---|---|

| Acute toxicity | Categories 1-4 (1 being the most dangerous) |

| Skin corrosion | Categories 1A, 1B, 1C, and 2 |

| Skin irritation | Categories 1A, 1B, 1C, and 2 |

| Eye Effects | Categories 1, 2A, and 2B |

| Sensitization (Skin or Eye) | Category 1A and 1B |

| Germ cell mutagenicity | Categories 1A, 1B, and 2 |

| Carcinogenicity | Categories 1A, 1B, and 2 |

| Reproductive toxicity | Categories 1A, 1B, 2, and additional category for effects on or via lactation |

| Target organ systemic toxicity | Single: Categories 1-3, Repeated: Categories 1 and 2 |

| Aspiration toxicity | Category 1 and 2 |

Environmental Hazards

Environmental hazards refer to substances that can have adverse effects on the environment, including aquatic life, air quality, and soil contamination. Here are some examples of hazard classes and their associated categories for environmental hazards:

| Hazard Class | Associated Hazard Category |

|---|---|

| Acute Aquatic Toxicity | Categories 1 – 3 |

| Chronic Aquatic Toxicity | Categories 1 – 4 |

Understanding the hazard classes and their applicable categories is essential for effectively managing and communicating hazards in the workplace. It allows employers to implement appropriate control measures, provide necessary training, and ensure the safety and well-being of employees.

Remember, accurate hazard classification and effective hazard communication are crucial elements of a comprehensive safety program. By prioritizing hazard classification and incorporating it into your workplace safety practices, you can create a safer work environment and mitigate potential risks.

Understand hazard categories

A hazard category is a classification within a hazard class that indicates the level of hazard or severity of a particular substance. Each hazard class can have one or more categories assigned to it. Categories are identified by numbers or alphabetical letters.

Here are some key points about hazard categories:

- Numbering and Lettering: Categories are assigned a number, such as 1, 2, 3, and so on. In some cases, alphabetical letters are used, like A, B, C, and so forth. For sub-categories, a combination of number and letter is used, such as 1A and 1B.

- Severity of Hazard: The category of a substance indicates how hazardous it is within its hazard class. Category 1 is always the highest level of hazard and represents the most severe or dangerous substances within that class. If further divided, Category 1A is more hazardous than Category 1B within the same hazard class. Similarly, Category 2 is more hazardous than Category 3, and so on.

- Varying Number of Categories: Hazard classes can have different numbers of categories. Some hazard classes have only one category, while others may have two, three, or even more categories. For example, the corrosive to metals hazard class has only one category, while carcinogenicity (cancer) may have two categories or oxidizing liquids may have three categories. There are a few hazard classes, like organic peroxides, that have five or more categories.

- Exceptions and Special Cases: There are exceptions to the general rule of numbering categories. For example, in the Gases under pressure hazard class, the categories are based on the physical state of the gas when packaged, rather than the degree of hazard. In the Reproductive Toxicity hazard class, there is a separate category called “Effects on or via lactation” that is not assigned a specific numbered category but is considered a related hazard within the class.

Understanding hazard categories helps in assessing the severity of a hazard and determining appropriate safety measures and precautions when dealing with hazardous substances.

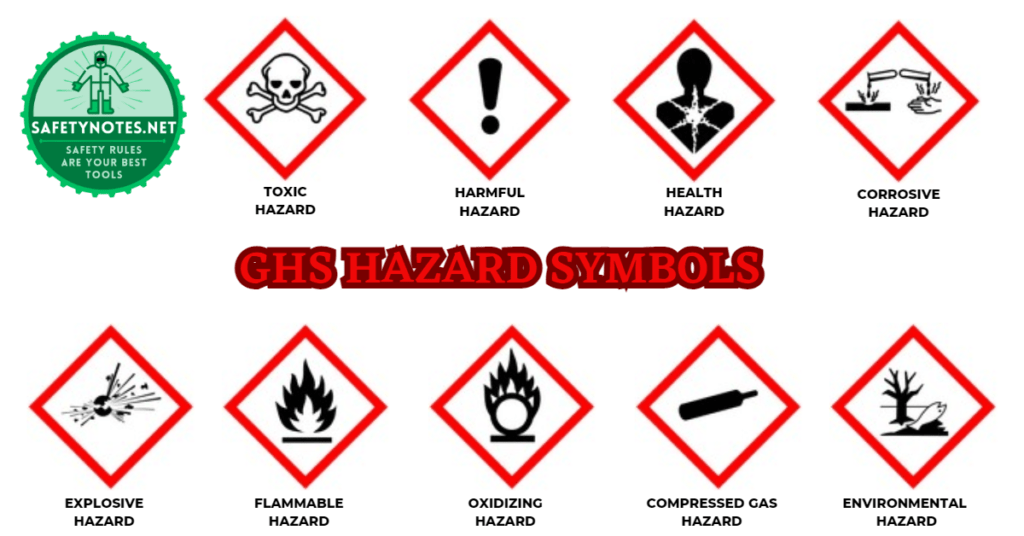

GHS Hazard Sign, Symbol Meanings

Health Hazard Symbols and Meanings

There are three GHS symbols used to warn about health hazards that can affect human health. These symbols provide important information about the potential risks associated with specific chemicals or substances. It is crucial to pay attention to these symbols and take the necessary precautions.

Toxic GHS Symbol

The toxic GHS symbol, commonly known as the skull-and-crossbones symbol, is used for chemicals with the highest levels of acute toxicity. These substances have an immediate and severe effect on human health, and exposure can occur through inhalation, ingestion, or skin contact. Always keep containers tightly closed until you have read more information and taken the recommended precautions.

Harmful GHS Symbol

The harmful GHS symbol, featuring an exclamation mark, is used for substances that are harmful or irritating. While the health effects are acute, they are generally less severe than those marked with the toxic symbol. This category includes skin, eye, or respiratory irritants, skin sensitizers, and substances with narcotic effects. Read the specific warnings and precautions on the label before handling these substances.

Health Hazard GHS Symbol

The health hazard GHS symbol is used for substances that pose a health hazard over time. This category includes carcinogens (causing cancer), respiratory sensitizers, reproductive toxicants, chemicals with target organ toxicity, mutagenic chemicals, and substances with aspiration toxicity. Make sure to read the label’s text for information on the specific health risks associated with these substances.

Physical Hazard Pictogram Meanings

Physical hazards are characteristics of substances that can pose risks to both property and human safety. There are five GHS symbols used to warn about physical hazards. It is crucial to understand these symbols and take appropriate precautions to prevent accidents or damage.

Corrosive GHS Symbol

The corrosive GHS symbol represents substances that can eat away at materials upon contact. This symbol covers both physical and health hazards. Corrosive substances can cause skin corrosion or burns, eye damage, or corrode metals. It is essential to leave containers tightly closed and consider safe handling and storage practices.

Explosive GHS Symbol

The explosive GHS symbol indicates that a chemical is unstable and has the potential to cause a fire or explosion. This symbol is used for explosives, self-reactive chemicals, and organic peroxides. It is crucial to gather more information and take necessary precautions before handling these substances.

Flammable GHS Symbol

The flammable GHS symbol is used for chemicals that emit flammable gas or could self-ignite when exposed to air or water. This category includes flammable gases, liquids, solids, pyrophoric materials, self-reactive materials, and water-reactive substances. Keep containers tightly closed and away from sources of heat or ignition until you have sufficient knowledge about the substance.

Oxidizing GHS Symbol

The oxidizing GHS symbol is used for oxidizing solids, liquids, and gases. These substances can facilitate combustion, making fires burn hotter and longer. Similar to the flammable symbol, this symbol indicates the need to keep containers tightly sealed and refrain from changing storage conditions or placing incompatible materials nearby.

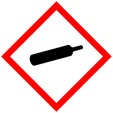

Compressed Gas GHS Symbol

The compressed gas GHS symbol is used for gases stored under pressure. This includes compressed gases, liquefied gases, refrigerated liquefied gases, and dissolved gases. Containers with this symbol may pose a risk of explosion if heated. Avoid touching these containers until you have obtained further information and are aware of the necessary handling precautions.

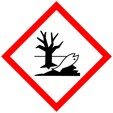

Environmental Hazard GHS Symbol – Pictogram Meanings

Only one of the GHS Symbo addresses an environmental hazard.

The environmental hazard GHS symbol indicates that a chemical is toxic to aquatic wildlife. While not mandatory, this symbol alerts users to take precautions to prevent environmental contamination. Ensure proper disposal methods and take measures to prevent the release of the substance into the environment during use or transportation.

Understanding these symbols and their meanings is crucial for ensuring safety in various settings. Always refer to the labels, follow recommended precautions, and seek additional information if needed to mitigate potential hazards.

Hazard Classification Process

The hazard classification process involves several steps that help identify and categorize hazards accurately. some of steps include data collection, hazard identification, hazard assessment etc.

Data Collection

The first step in hazard classification is gathering relevant information about the substance or material in question. This includes collecting data on the substance’s physical and chemical properties, toxicity, and potential hazards.

Hazard Identification

Based on the collected data, hazards associated with the substance are identified. This step involves assessing the potential risks, considering factors such as flammability, reactivity, toxicity, and environmental impact.

Hazard Assessment

Hazard assessment involves determining the severity and likelihood of harm associated with a particular hazard. This step helps prioritize risks and establish appropriate control measures.

Hazard Communication (HazCom) Program

Hazard communication (HazCom) is the process of conveying information about hazardous materials to employees. It ensures that workers are aware of the potential hazards associated with the materials they handle and use. Effective hazard communication (HazCom) is crucial for promoting workplace safety and reducing the risk of accidents and injuries.

Employers that use hazardous chemicals in their workplaces are required by OSHA’s Hazard Communication Standard (HCS) to implement a hazard communication (HazCom) program. This program must include labels on containers of hazardous chemicals, safety data sheets (SDSs) for hazardous chemicals, and training for workers. To implement an effective hazard communication program, employers can follow these six steps:

Step 1. Learn the Standard/Identify Responsible Staff

- Obtain a copy of OSHA’s Hazard Communication Standard and become familiar with its provisions.

- Assign someone with primary responsibility for coordinating the implementation of the program.

- Identify staff members for specific activities such as training.

Step 2. Prepare and Implement a Written Hazard Communication (HazCom) Program

- Employers should develop a written hazard communication program that outlines their approach to hazard identification, classification, communication, and training. The program should comply with regulatory requirements and be tailored to the specific hazards present in the workplace.

- Once developed, the hazard communication program needs to be implemented effectively. This involves assigning responsibilities, establishing communication channels, and integrating hazard communication practices into daily operations.

Step 3. Ensure Containers are Labeled

- Keep labels on shipped containers received from chemical manufacturers and importers.

- Label workplace containers where required.

- Labels should include the product identifier and general information about the hazards of the chemical.

- Proper labeling of hazardous materials is essential for hazard communication. Labels provide important information about the hazards, handling precautions, and emergency response measures.

- A hazardous material label typically includes elements such as product name, hazard pictograms, signal words (e.g., “danger” or “warning”), precautionary statements, and supplier information.

Step 4. Maintain Safety Data Sheets (SDSs)

- Safety Data Sheets (SDS), also known as Material Safety Data Sheets (MSDS), provide detailed information about hazardous substances. They include information about the substance’s properties, handling procedures, emergency measures, and regulatory compliance.

- Maintain SDSs for each hazardous chemical in the workplace.

- Ensure that SDSs are readily accessible to employees in their work areas.

- Determine the most suitable method of maintaining and providing access to SDSs, whether through a physical binder or an electronic system.

Step 5. Inform and Train Employees

- Train employees on the hazardous chemicals in their work area before their initial assignment and when new hazards are introduced.

- Include information about the requirements of the standard, hazards of chemicals, appropriate protective measures, and how to obtain additional information.

- Ensure that the training is conducted in a manner and language that employees can understand.

- Effective training and education programs are vital for ensuring workplace safety and promoting hazard awareness among employees. Training should cover topics such as hazard identification, proper handling and storage of hazardous materials, emergency response procedures, and the use of personal protective equipment.

- Regular refresher training sessions should be conducted to keep employees updated on new hazards, regulations, and best practices.

Step 6. Evaluate and Reassess Your Program

- Periodically review your hazard communication program to ensure it is still effective and meeting its objectives.

- Revise the program as needed to address any changed conditions in the workplace, such as the introduction of new chemicals or hazards.

It is important for employers to familiarize themselves with the specific requirements of the Hazard Communication (HazCom) Standard and ensure compliance in their workplaces. By following these steps and maintaining an effective hazard communication (HazCom) program, employers can promote workplace safety and protect their employees from the hazards associated with hazardous chemicals.

For more detailed information on implementing an effective hazard communication (HazCom) program, refer to OSHA’s Hazard Communication: Small Entity Compliance Guide for Employers That Use Hazardous Chemicals.

Hazard Communication (HazCom) Challenges

While hazard classification is crucial for workplace safety, there are challenges that organizations may face in implementing effective hazard communication programs. Some common challenges include:

Language and Cultural Barriers

In diverse workplaces, language barriers can hinder effective hazard communication. It is important to provide information and training in languages understood by all employees. Cultural differences in understanding and perceiving hazards also need to be considered to ensure effective communication.

Updating and Maintaining Information

Hazard communication requires up-to-date and accurate information about hazards. However, keeping track of changes in regulations, chemical compositions, and safety data can be challenging. Employers must establish systems and procedures to regularly review and update hazard information.

Handling Data Sheets and Documentation

Safety data sheets (SDS) provide critical information about hazardous substances, including their properties, handling procedures, and emergency response measures. Maintaining up-to-date SDS and organizing documentation can be overwhelming, particularly for organizations with a wide range of chemicals. Employers need efficient systems to manage SDS, ensure accessibility, and enable quick retrieval during emergencies

Hazardous Chemicals in Non-Traditional Workplaces

Hazard communication challenges are not limited to traditional workplaces. With the rise of remote work, gig economy, and non-traditional work arrangements, ensuring hazard communication in such environments becomes more complex. Employers must find innovative ways to deliver information and training to individuals who may not have a physical presence in a centralized workplace.

Addressing Misinterpretation and Miscommunication

Despite best efforts, misinterpretation and miscommunication of hazard information can occur. Ambiguity, confusion, or misunderstanding may lead to incorrect handling of hazardous substances, potentially endangering employees’ safety. Employers should encourage open dialogue, provide clarification when needed, and continuously assess the effectiveness of their communication strategies.

Dealing with Emergencies and Incident Response

In emergency situations, effective hazard communication is crucial for mitigating risks and ensuring a prompt and coordinated response. However, challenges arise when communicating critical information during high-stress events. Establishing emergency protocols, conducting drills, and leveraging technology can enhance communication efficiency and help minimize the impact of emergencies.

HazCom in a Globalized Workforce

Globalization has transformed workplaces into diverse environments, with employees from various cultural backgrounds and different regulatory frameworks. Harmonizing hazard communication practices across borders can be challenging due to varying regulations and cultural norms. Organizations operating internationally must navigate these complexities by developing standardized approaches while considering local requirements.

FAQs (Frequently Asked Questions)

What is the purpose of hazard classification?

Hazard classification serves the purpose of identifying and categorizing hazards based on their characteristics and risks. It helps organizations and individuals understand the nature of hazards and implement appropriate safety measures.

Why is it important to categorize physical hazards?

Categorizing physical hazards allows for a better understanding of their potential dangers and enables the implementation of specific control measures. It helps in assessing the severity of hazards and prioritizing safety measures accordingly.

How does hazard classification benefit employees?

Hazard classification benefits employees by raising awareness about potential hazards in the workplace. It allows them to understand the risks associated with certain substances or materials and take necessary precautions to protect themselves.

Can hazard classification change over time?

Yes, hazard classification can change over time. As new research and data become available, the understanding of hazards may evolve, leading to updates in their classification. It is important to stay updated with the latest information and adjust safety measures accordingly.

Who is responsible for hazard classification in the workplace?

Employers are primarily responsible for hazard classification in the workplace. They should ensure that proper procedures are in place to identify and classify hazards accurately. In some cases, external experts or consultants may be involved to provide specialized knowledge and assistance.

What does the toxic GHS symbol represent?

The toxic GHS symbol represents chemicals with the highest levels of acute toxicity. These substances have an immediate and severe effect on human health and can be lethal in some cases.

What does the corrosive GHS symbol indicate?

The corrosive GHS symbol is used for substances that can cause corrosion or burns to the skin, eye damage, or corrosion to metals. It is important to handle these substances with caution and follow proper safety protocols.

Which category of substances does the harmful GHS symbol cover?

The harmful GHS symbol is used for substances that are harmful or irritating. It includes skin, eye, or respiratory irritants, skin sensitizers, substances with narcotic effects, and chemicals with lower levels of acute toxicity.

What does the environmental hazard GHS symbol signify?

The environmental hazard GHS symbol indicates that a chemical is toxic to aquatic wildlife. Precautions should be taken to prevent environmental contamination and to use proper disposal methods.

Why is it important to understand physical hazard symbols?

Understanding physical hazard symbols is crucial for identifying potential risks associated with substances. It helps individuals take appropriate precautions to prevent accidents, fires, explosions, and other physical hazards.

How can employers ensure compliance with hazard communication regulations?

Employers can ensure compliance by staying updated with the latest regulations, conducting regular audits, providing comprehensive employee training, and maintaining accurate documentation of hazardous substances.

What should employers consider when communicating hazards to non-English speaking employees?

Employers should adopt multilingual approaches, use visual aids, and provide translated materials to ensure effective communication with non-English speaking employees.